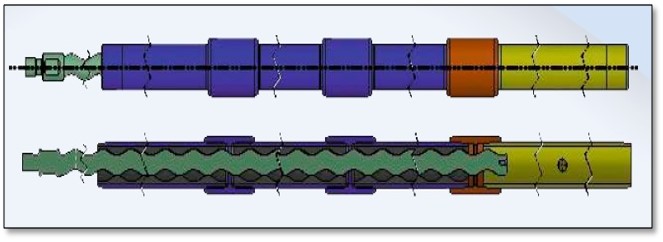

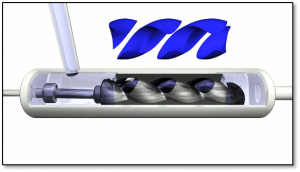

The operation principle of the progressive cavity pump (PCP) is a helical rotor of steel with circular profile that rotates inside a stator with double the pitch, that is made of an elastomer, normally vulcanized inside a carcass of carbon steel.

The operation principle of the progressive cavity pump (PCP) is a helical rotor of steel with circular profile that rotates inside a stator with double the pitch, that is made of an elastomer, normally vulcanized inside a carcass of carbon steel.

Depending on the geometry of the rotor and the stator, sealed cavities between suction and discharge are formed. The opening and closing of these cavities creates a depression in the suction nozzle, which causes the fluid to be suctioned and develops a volumetric flow directly proportional to its rotation.

Progressive cavity pumps have many advantages. Here are some of them:

• Progressive cavity pump is able to operate with much lower suction pressure than rod pumps. As a result, the well column requires less fluid to feed the pump. Under atmospheric suction pressure, it can function with the fluid level of the well close to the suction intake of the pump without affecting its performance. This enables well production to be increased to the maximum level of fluid available.

• The PCP pumps do not require a heater, even when pumping high viscosity oils.

• Pumps oil and water with solids.

• No internal valves to clog or gas lock.

• Continuous smooth operation helps in preventing and controlling production of undesired reservoir fluids and particles.

• Minimal maintenance costs.